|

һ���a(ch��n)Ʒ��(ji��n)�飺

���Ã�(y��u)�|(zh��)ԭ�������M(j��n)�ں��IJ��������M(j��n)�����a(ch��n)��ˇ��������(y��n)��ęz�y(c��)���a(ch��n)����ʽ���t������(xi��ng)���g(sh��)ָ��(bi��o)���_(d��)����(gu��)�H���M(j��n)ˮƽ������ɏV����(y��ng)���ڿ��������̌W(xu��)���������V��I(y��)�еČ�(sh��)�(y��n)������̎������۽����������Y(ji��)�����ú�������ԵĜy(c��)����������

��������a(ch��n)Ʒ���c(di��n)��

1��������p�Ӡt�������пո���������(qi��ng)��ͨ�L(f��ng)�T����(gu��)�H���M(j��n)���O(sh��)Ӌ(j��)����_���⚤���C����(n��i)��Ѹ�ٽ��ص����c(di��n)���Ɍ�(sh��)�F(xi��n)�������������

2���t�T(m��n)�������(c��)�_(k��i)��ʽ�O(sh��)Ӌ(j��)�������Ñ�(h��)����������

3�����t���x���M(j��n)�ڰ�ʽ�մ��w�S�t�ţ���ӟ�Ԫ�����ÃɄt�r��ʽ������t��(n��i)�ضȷֲ������Ժ�������������ٶȿ졢�ɸ��Q������(ji��)���@��������Ч�ʸ��������ɴ����ƹ����ˆT�Č�(sh��)�(y��n)�h(hu��n)����

4���������(bi��o)�䎧�в��P䓲��|(zh��)�L(f��ng)ñ�����P䓲��|(zh��)�ğ��裬���^������������������

5��������Ʋ���ȫ���x���ձ��u������Wķ��?ji��n)��b���������ܿɿ���

6�������(bi��o)��4*10���Ծ��س��������������(sh��)�(y��n)Ҫ�������O(sh��)����������������^(gu��)������

7��������ò��P��z�b���ż�������з���(y��ng)�`�����ؾ��ȸ�������͜��Ժõă�(y��u)�c(di��n)�������

8��������O(sh��)�з�ֹ��늻������ͣ�C(j��)���(l��i)��`����(d��ng)�������

9������t�T(m��n)�O(sh��)�пɿ����_(k��i)�T(m��n)����_(k��i)�P(gu��n)���_�������ˆT��ȫ��

10�������O(sh��)���^(gu��)������^(gu��)�������ż����������ر��o(h��)�ȶ��(xi��ng)��ȫ���o(h��)��ʩ������ֹ����l(f��)�����

11�����x�䣺�o(w��)��ӛ䛃x��С�L(zh��ng)�Dӛ䛃x�����A�P(p��n)ӛ䛃x�����

12���ӟ�Ԫ�����x�Ã�(y��u)�|(zh��)�t�z������ܷ�(w��n)���������ɿ��������L(zh��ng)����

13���t�T(m��n)�������t�ڲ��ò��P䓲�������������иߜز�׃ɫ�����c(di��n)��

14���Ԅ�(d��ng)ƽ�Љ����t�T(m��n)��(zhu��n)�����g(sh��)����_���t��(n��i)�ߜز���й����t��(n��i)�ضȾ���������

15�����@ʾ��ʽ���x��5��Һ���@ʾ�������������ȫ�|��ʽ���I���������������������(sh��)�r(sh��)�O(ji��n)�����

���� ��(chu��ng)���c(di��n)�O(sh��)Ӌ(j��)

1��������p�Ӡt�����пո���������(qi��ng)��ͨ�L(f��ng)�T����(gu��)�H���M(j��n)���O(sh��)Ӌ(j��)����_���⚤���C�������(n��i)��Ѹ�ٽ��ص����c(di��n)������Ɍ�(sh��)�F(xi��n)���������������

2�����Ԅ�(d��ng)ƽ�Љ����t�T(m��n)��(zhu��n)�����g(sh��)�������_���t��(n��i)�ߜز���й������t��(n��i)�ضȾ�������

3����O(sh��)���^(gu��)���������^(gu��)����������ż���ϡ����ر��o(h��)�ȶ��(xi��ng)��ȫ���o(h��)��ʩ����ֹ����l(f��)�����

4��5�糬��Һ���@ʾ����ȫ�|��ʽ���I����������������(sh��)ʩ�O(ji��n)�ء�

5��������t�T(m��n)���t�ڲ��ò��P䓲��ϣ����иߜز�׃ɫ�����c(di��n)���

�ġ����g(sh��)ָ��(bi��o)

��̖(h��o)��ETT-1200C-2L-TP

���g(sh��)Ҏ(gu��)��

1���t�ųߴ磺200X120X80

2���t���ݷe��2L

3���t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4�������O(sh��)Ӌ(j��)�ضȣ�1200��

5�������������PLC����ϵ�y(t��ng)

6���ؾ��ȣ���1��

7��������������������ʣ����أ�50��/min�����أ�5��/min

8��������ӟ�Ԫ������(y��u)�|(zh��)늠t�z

9�����������K�ֶȣ����P��z�b

10��������~�ȹ��ʣ�2.5KW

11�������������12A

12���t�w���⚤������܈��䓰壬��(n��i)�T(m��n)���ò��P���������p�әC(j��)������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

13��������γߴ磺480X400X570

ע��������x��늠t��Pϵ�������30�������60�ɷN���

-------------------------------------------

��̖(h��o)��ETT-1200C-7L-TP

���g(sh��)ָ��(bi��o)

1����t�ųߴ磺300X200X120

2���t���ݷe��7.2L

3������t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4��������O(sh��)Ӌ(j��)�ضȣ�1200��

5�����������PLC����ϵ�y(t��ng)

6�����ؾ��ȣ���1��

7���������������ʣ����أ�50��/min�����أ�5��/min

8��������ӟ�Ԫ������(y��u)�|(zh��)늠t�z

9����������K�ֶȣ����P��z�b

10������~�ȹ��ʣ�4KW

11������������19A

12��������t�w���⚤������܈䓰������(n��i)�T(m��n)���ò��P������p�әC(j��)���������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

13������γߴ磺590X520X620

ע��������x��늠t��Pϵ��������30�Ρ�60�ɷN

--------------------------------------------------

��̖(h��o)��ETT-1200C-12L-TP

���g(sh��)Ҏ(gu��)��

1�����t�ųߴ磺300X200X200

2��������t���ݷe��12L

3������t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4�������O(sh��)Ӌ(j��)�ضȣ�1200��

5���������PLC����ϵ�y(t��ng)

6�����ؾ��ȣ���1��

7�����������������ʣ����أ�50��/min�����أ�5��/min

8���ӟ�Ԫ������(y��u)�|(zh��)늠t�z

9�������������K�ֶȣ����P��z�b

10�����~�ȹ��ʣ�4KW

11������������19A

12�������t�w���⚤������܈��䓰壬��(n��i)�T(m��n)���ò��P䓣��p�әC(j��)��������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

13���������γߴ磺670X530X700

ע��������x��늠t��Pϵ����������30������60�ɷN�������

-----------------------------------------------

��̖(h��o)��ETT-1200C-36L-TP

���g(sh��)ָ��(bi��o)

1���t�ųߴ磺400X300X300

2�������t���ݷe��36L

3�����t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4��������O(sh��)Ӌ(j��)�ضȣ�1200��

5��������PLC����ϵ�y(t��ng)

6������ؾ��ȣ���1��

7����������������������ʣ����أ�50��/min��������أ�5��/min

8������ӟ�Ԫ������(y��u)�|(zh��)늠t�z

9������������K�ֶȣ����P��z�b

10��������~�ȹ��ʣ�8KW

11����t�w���⚤������܈��䓰壬��(n��i)�T(m��n)���ò��P䓣��p�әC(j��)�������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

ע��������x��늠t��Pϵ����������30�������60�ɷN�������

===================================

��̖(h��o)��ETT-1700C-3.6L-TP

���g(sh��)Ҏ(gu��)��

1������t�ųߴ磺160X150X150

2����t���ݷe��3.6L

3���t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4�������O(sh��)Ӌ(j��)�ضȣ�1700��

5��������������x��PLC����ϵ�y(t��ng)

6�������ؾ��ȣ���1��

7�������������ʣ����أ�50��/min���������أ�5��/min

8���ӟ�Ԫ����U��1800ϵ�й��f��

9����������B�ֶȣ��K��K

10��������~�ȹ��ʣ�4KW

11���t�w���⚤������܈䓰壬��(n��i)�T(m��n)���ò��P���������p�әC(j��)������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

12���������γߴ磺680X500X660

------------------------------------------------

��̖(h��o)��ETT-1700C-5.6L-TP

���g(sh��)Ҏ(gu��)��

1�����t�ųߴ磺250X150X150

2��������t���ݷe��5.6L

3���t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4�������O(sh��)Ӌ(j��)�ضȣ�1700��

5���������x��PLC����ϵ�y(t��ng)

6�����ؾ��ȣ���1��

7����������������������ʣ����أ�50��/min������أ�5��/min

8���ӟ�Ԫ����U��1800ϵ�й��f��

9�����������B�ֶȣ��K��K

10���~�ȹ��ʣ�6KW

11������t�w���⚤������܈䓰��������(n��i)�T(m��n)���ò��P������p�әC(j��)����������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

12�����γߴ磺730X1000X740 ------------------------------------------------------

��̖(h��o)��ETT-1700C-13L-TP

���g(sh��)Ҏ(gu��)��

1����t�ųߴ磺400X200X160

2�������t���ݷe��13L

3����t�Ų��ϣ��M(j��n)�ڸ��ܶ��մ��w�S

4�����O(sh��)Ӌ(j��)�ضȣ�1700��

5����������x��PLC����ϵ�y(t��ng)

6�������ؾ��ȣ���1��

7��������������ʣ����أ�50��/min������أ�5��/min

8���ӟ�Ԫ����U��1800ϵ�й��f��

9�������������B�ֶȣ��K��K

10������~�ȹ��ʣ�12KW

11���t�w���⚤������܈䓰壬��(n��i)�T(m��n)���ò��P�������p�әC(j��)����������(bi��o)��ѭ�h(hu��n)�L(f��ng)��ϵ�y(t��ng)

12�������γߴ磺850X1060X820

=======================================

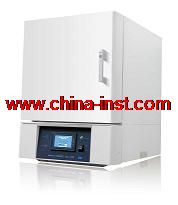

I. Introduction :

Using high-quality raw materials, imported core components, advanced production technology , strict testing produced box-type resistance furnace . Its various technical indicators have reached the international advanced level. It can be widely used in scientific research , teaching, industrial and mining enterprises in the laboratory for heat treatment , melting, sintering, etc. Determination of ash fusion .

Second, product characteristics :

1 , double furnace shell , hollow insulation, powerful ventilation many international advanced design concepts to ensure that housing is not hot , rapid cooling of the inner shell features , enabling fast movements .

2 , using the left door open design, user-friendly operation .

3 , hearth plate made of imported ceramic fiber furnace , the heating element is a two- liner style , the furnace temperature uniformity is good, with heating speed, can be replaced , significant energy saving , high efficiency, and can greatly improve the experimental staff environment.

4 , standard chimney hood with stainless steel and stainless steel , beautiful, elegant, and durable.

5, the electrical control all use Japanese island , Omron original accessories, reliable performance.

6 , standard 4 * 10 segments self temperature control procedures can be set up according to the experimental requirements on their own , the cooling process .

7 , the use of stainless steel sheathed thermocouple , with responsive, high precision temperature control , temperature resistance and good benefits .

8 features to prevent power outages or downtime due to the false start function calls .

9 , open the door with a reliable power switch , ensure operator safety.

10 , with over- current, over voltage , thermocouple failure , overtemperature protection and many other safety precautions. Prevent accidents.

11 , optional : paperless recorder , a small strip chart recorder, disc recorder, etc. .

12 , heating elements : high quality furnace wire , stable performance, reliable, long life .

13 , door, furnace mouth of stainless steel, high temperature does not change color characteristics.

14 , automatic parallel pressure door patented technology to ensure no leakage of high temperature furnace , the furnace temperature uniformity.

15 , Display: Optional 5-inch LCD controller , full touch buttons . Liter , cooling curve real-time monitoring .

Third, innovation design

1 , double furnace shell , hollow insulation, powerful ventilation many international advanced design concepts to ensure that housing is not hot , rapid cooling of the inner shell features , enabling rapid heating and cooling .

2, automatic parallel pressure door patented technology to ensure no leakage of high temperature furnace , the furnace temperature uniformity.

3 , with over- current, over voltage , thermocouple failure , overtemperature protection and many other security measures to prevent accidents.

4,5 inch large LCD screen, full- touch buttons , up , monitoring the implementation of the cooling curve .

5 door , stainless steel mouth , does not change color with temperature characteristics .

Fourth, the technical indicators

Model : ETT-1200C-2L-TP

Technical Specifications:

1 , furnace size : 200X120X80

2, the furnace volume : 2L

3 , the furnace material : imported high density ceramic fiber

4, the design temperature : 1200 ��

5, the temperature control : PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8, the heating elements : high quality electric wire

9 , the sensor : K indexing : stainless steel armor

10 , the amount of power: 2.5KW

11 Current : 12A

12 , the furnace : the shell is made of cold-rolled sheet steel , stainless steel inner door ; double chassis , standard cycle air cooling system

13 , Dimension : 480X400X570

Note: The furnace temperature controller with a program for the P-series , there are two 30 segments, 60 segments.

-------------------------------------------

Model : ETT-1200C-7L-TP

Technical indicators

1 , the chamber dimensions : 300X200X120

2, the furnace volume : 7.2L

3 , the furnace material : imported high density ceramic fiber

4, the design temperature : 1200 ��

5, the temperature control : PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8, the heating elements : high quality electric wire

9 , the sensor : K indexing : stainless steel armor

10 , the amount of power : 4KW

11 Current : 19A

12 , the furnace : shell is made of cold rolled steel, stainless steel inner door ; double chassis , standard cycle air cooling system

13 , Dimension : 590X520X620

Note: The furnace temperature controller with a program for the P-series , there are 30 segments, 60 segments in two

--------------------------------------------------

Model : ETT-1200C-12L-TP

Technical Specifications:

1 , the chamber dimensions : 300X200X200

2, the furnace volume : 12L

3 , the furnace material : imported high density ceramic fiber

4, the design temperature : 1200 ��

5, the temperature control : PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8, the heating elements : high quality electric wire

9 , the sensor : K indexing : stainless steel armor

10 , the amount of power : 4KW

11 Current : 19A

12 , the furnace : the shell is made of cold-rolled sheet steel , stainless steel inner door ; double chassis , standard cycle air cooling system

13 , Dimension : 670X530X700

Note: The furnace temperature controller with a program for the P-series , there are two 30 segments, 60 segments.

-----------------------------------------------

Model : ETT-1200C-36L-TP

Technical indicators

1 , the chamber dimensions : 400X300X300

2, the furnace volume : 36L

3 , the furnace material : imported high density ceramic fiber

4, the design temperature : 1200 ��

5, the temperature control : PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8, the heating elements : high quality electric wire

9 , the sensor : K indexing : stainless steel armor

10 , the amount of power : 8KW

11 , the furnace : the shell is made of cold-rolled sheet steel , stainless steel inner door ; double chassis , standard cycle air cooling system

Note: The furnace temperature controller with a program for the P-series , there are two 30 segments, 60 segments.

===================================

Model : ETT-1700C-3.6L-TP

Technical Specifications:

1 , the chamber dimensions : 160X150X150

2, the furnace volume : 3.6L

3 , the furnace material : imported high density ceramic fiber

4 , the design temperature : 1700 ��

5, the temperature control : use PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8 , the heating element : U -type silicon molybdenum rod 1800 Series

9 , the sensor : B indexing : platinum and rhodium platinum

10 , the amount of power : 4KW

11 , the furnace : shell is made of cold rolled steel, stainless steel inner door ; double chassis , standard cycle air cooling system

12 , Dimension : 680X500X660

------------------------------------------------

Model : ETT-1700C-5.6L-TP

Technical Specifications:

1 , the chamber dimensions : 250X150X150

2, the furnace volume : 5.6L

3 , the furnace material : imported high density ceramic fiber

4 , the design temperature : 1700 ��

5, the temperature control : use PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8 , the heating element : U -type silicon molybdenum rod 1800 Series

9 , the sensor : B indexing : platinum and rhodium platinum

10 , the amount of power : 6KW

11 , the furnace : shell is made of cold rolled steel, stainless steel inner door ; double chassis , standard cycle air cooling system

12 , Dimensions : 730X1000X740

-------------------------------------------------- ----

Model : ETT-1700C-13L-TP

Technical Specifications:

1 , the chamber dimensions : 400X200X160

2, the furnace volume : 13L

3 , the furnace material : imported high density ceramic fiber

4 , the design temperature : 1700 ��

5, the temperature control : use PLC control system

6 , temperature accuracy : �� 1 ��

7 liters, cooling rate: temperature : 50 �� / min; cooling : 5 �� / min

8 , the heating element : U -type silicon molybdenum rod 1800 Series

9 , the sensor : B indexing : platinum and rhodium platinum

10 , the amount of power : 12KW

11 , the furnace : shell is made of cold rolled steel, stainless steel inner door ; double chassis , standard cycle air cooling system

12 , Dimensions : 850X1060X820 |

MSN�ͷ�

MSN�ͷ�